The production process of disc fertilizer granulator is short, simple structure, less investment and easy to operate. It is suitable for small and medium enterprises. Raw materials are widely adaptable. Nitrogen source including urea, ammonium chloride, ammonium sulfate, ammonium bicarbonate etc.. Phosphorus source including calcium superphosphate, heavy calcium, monoammonium phosphate, diammonium phosphate, calcium magnesium phosphate etc..

Potassium sources including potassium chloride, potassium sulfate and so on. This production line can produce inorganic compound fertilizer, organic fertilizer, organic (inorganic) compound fertilizer, biological organic fertilizer and other products with 20~48% content of nitrogen, phosphorus, potassium.

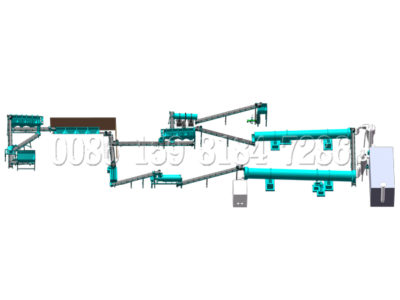

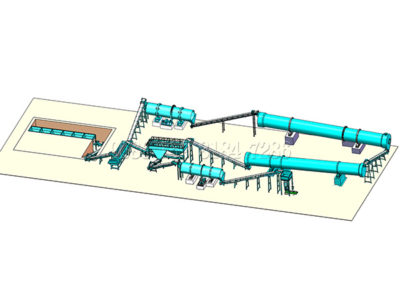

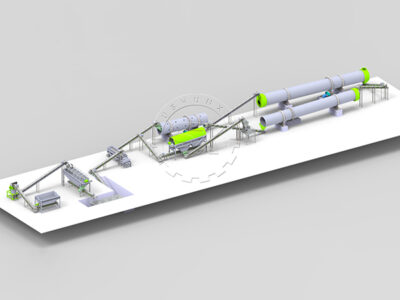

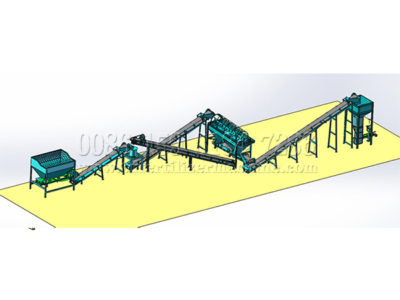

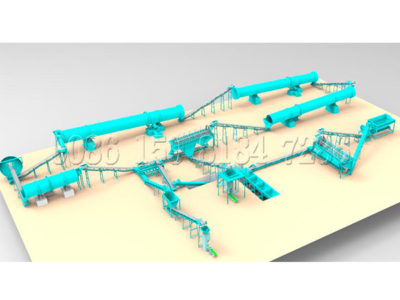

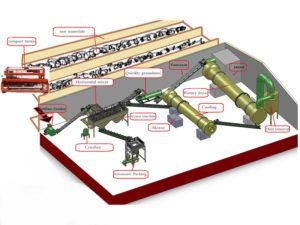

Brief introduction of compound fertilizer disc granulation process:

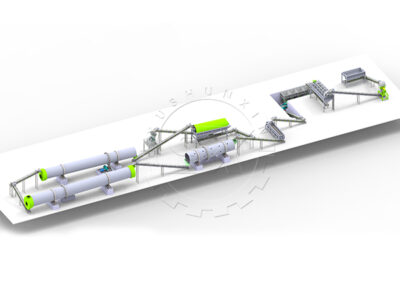

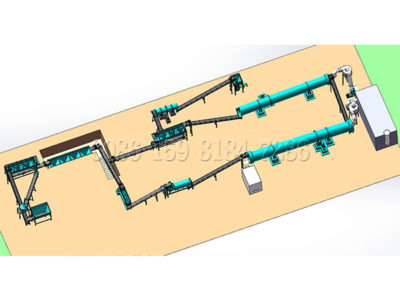

- Transport the nitrogen, phosphorus, potassium, filling material and other qualified raw materials to the relevant weighing equipment.

- Transfer the raw materials after weighing to mixer and strong stirring evenly.

- Transfer the mixed raw materials to the material distributor and evenly add the materials to the rotating disk of the disc granulator. A liquid component or a suitable amount of water is sprinkled on the material in the disk by a liquid distributor of disk granulator to satisfy the required amount of liquid content for pelletizing. The rotating disk and disk edge produce friction and centrifugal action on the material, cause the material to produce circumferential movement, so that the particles kneading and extruding between each other and gradually aggregated into balls. Due to the different weight of particles, the gravity and centrifugal effects are different.

When the gravity and centrifugal effect are big enough to overcome the friction between the particles, then the particles will be thrown outside the disc, and smaller particles remain in the disc continue to aggregate fine particles.

- Transfer the particles to the rotary dryer for drying.

- Deliver to rotary cooling machine, cooling fertilizer particles through natural air or forced air.

- Transport the cooling fertilizer granules to the screen machine. The fine particles after screening will directly return to the material distributor, and the large particles will be crushed by the crusher and then return to the material distributor.

- The qualified products will be sent to coating machine for coating.

- Deliver to the full automatic packing scale to weighing, packing and put in storage.

- Dust in drying, cooling and the workshop will discharge after three stages treatment: cyclone dust collector, labyrinth dust chamber and wet scrubbing.

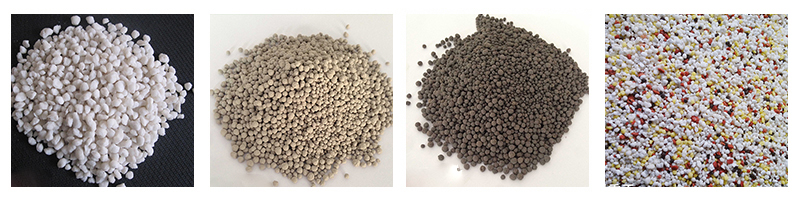

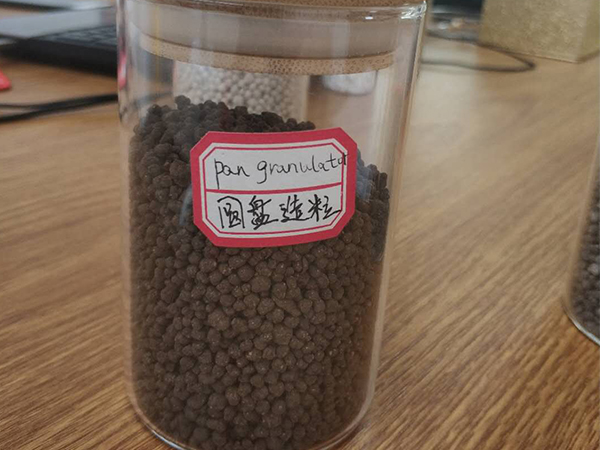

Sample particles: