Compound fertilizer can supply comprehensive nutrient for crops. The production process of compound fertilizer is to combine the main nutrient elements needed for crops (such as N, P, K and other trace elements) by chemical method, that is, gather the nitrogen fertilizer, phosphorus fertilizer, potash fertilizer and other chemicals together and make into particles which are suitable for farming. Then applied into the soil, so that crops can absorb the nutrients they need from soil.

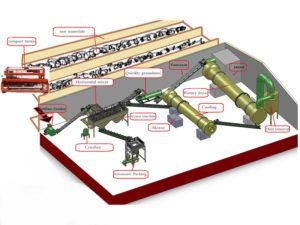

The principle of production process is as following: first, ammoniation of phosphate fertilizer (scientific name “superphosphate”), second, produce compound fertilizers by a variety of powdered raw materials through granulation, drying and cooling process.

Monomer based fertilizers such as urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, calcium carbonate, calcium superphosphate), potassium chloride (potassium sulfate) as raw materials, after grinding to a certain fineness, the materials are wetting, heating and agglomeration and granulation in the rolling bed of rotary drum granulator. In the granulation process, if possible, users can also add a small amount of phosphoric acid and ammonia into the rotary drum granulator to improve the granulation conditions.

The granulation material is dried, screened and cooled to become NPK compound fertilizer products. There is no environmental pollution in the production process of compound fertilizer by rotary drum granulator. As most of the basic fertilizer in our country is powdery and granular, so this method is mostly used in small and medium scale compound fertilizer plants in our country.

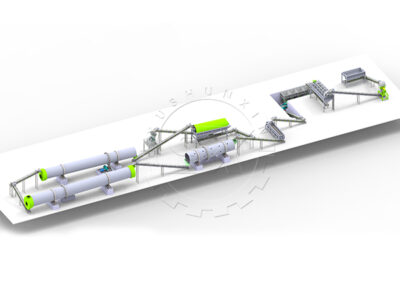

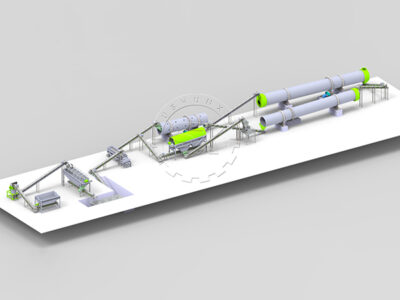

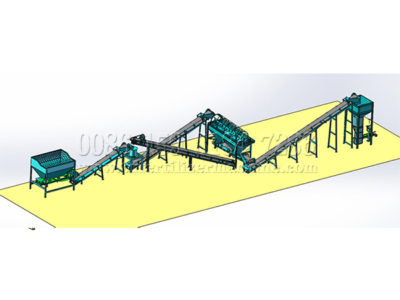

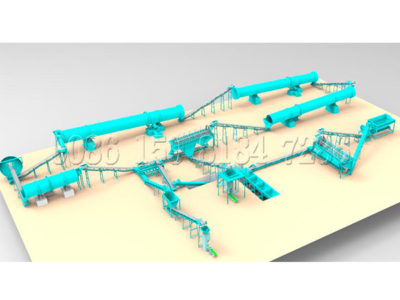

The technological process of compound fertilizer production line is divided into following parts: raw material batching, raw material mixing, raw material granulation, particles drying, particles screening, particles cooling and finished product packaging.

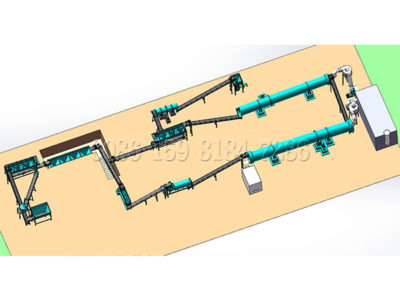

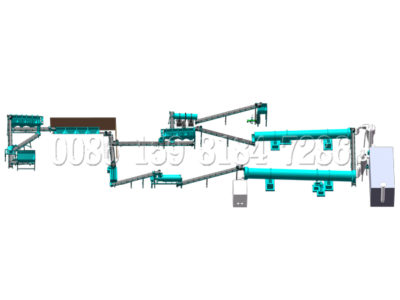

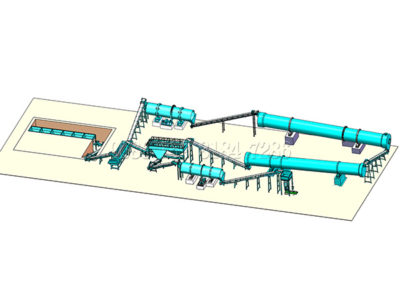

Our customers’ plants:

Sample particles:

-Fertilizer-Production-Line.jpg)