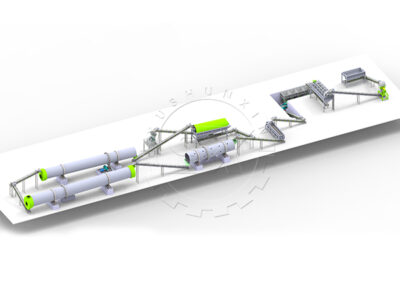

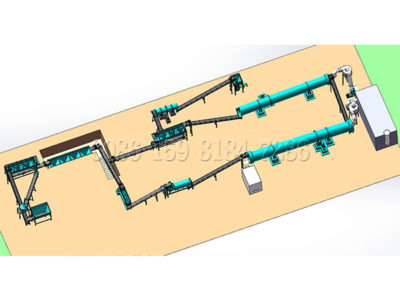

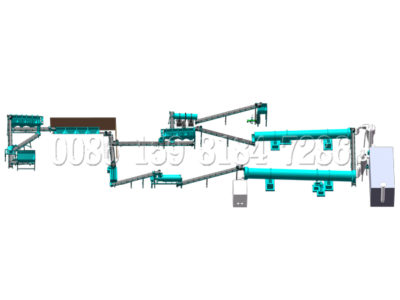

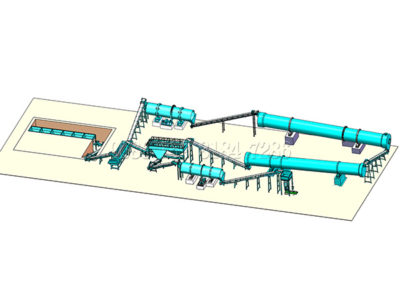

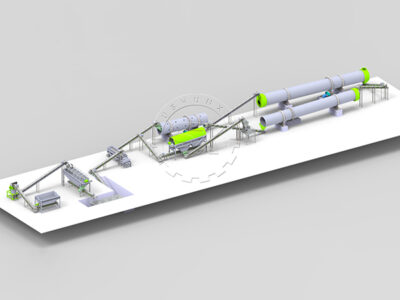

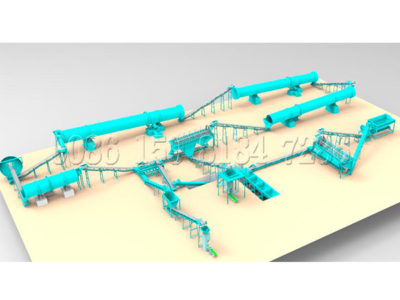

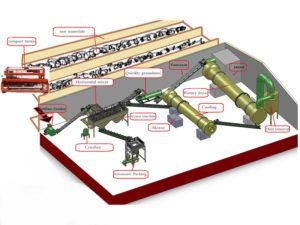

First of all, after the fermentation of organic fertilizer raw materials(animal manure, domestic garbage, dead leaves, waste residue, bacteria etc.), they will be crushed by semi wet material crusher. Then add nitrogen, phosphorus, potassium and other elements(pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc.) so that make the mineral elements contained in the organic fertilizer raw materials meet the required standards, and then using the mixer machine to mix all these organic materials. Finally, they will be transported to the new type organic fertilizer granulator to granulate.

After granulating, the organic fertilizer granules will be dried by drum drier, and screened by the screening machine. The qualified products will be packaged and the unqualified products will be returned to the granulator to granulation again.

- Raw material ratio per ton:

Cow dung 500 kg + duck manure 300 kg + fungus residue 200 kg + RW microbial inoculum 100 grams(above cow dung or duck dung can be replaced by other livestock manure)

- Heap

According to the above material ratio and necessary need to heap the raw materials, the pile length is not limited, and the width of 2 meters, height 1 meters. In the pile, it is necessary to stack the material evenly.

- Adding microbial inoculum

Increase the volume of bacterial inoculum by using fungus residue with the ratio of 1:5, then evenly spread to the surface of the pile according to the number of heaps.

- Mixing and fermentation

Mixing the mixture with mixer machine, when the temperature rose to 60 degrees or more, turning the materials heaps once each 4-5 days apart. After 15 days above 60 degrees fermentation, then the raw materials can be put away.

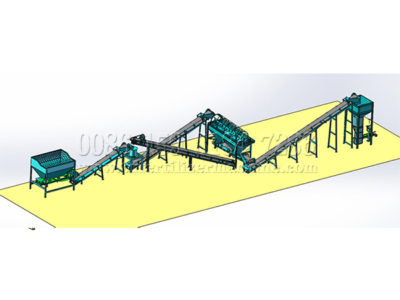

- Screen processing

After fermentation according to the above steps, then screening and deep processing, the raw materials become pure organic fertilizer.

- Granulating

To granulate the fermented pure organic fertilizer. Choose different granulator according to the different raw materials, such as new type organic fertilizer granulator, disc fertilizer granulator, double roller depress granulator, flat-die granulator, fertilizer round polishing machine and so on.

- Drying, cooling and packing

The moisture content of the newly made particles is relatively large, so water should be dried 20% or less according to standards organic fertilizer. The dried granule organic fertilizer is directly packaged after being cooled by the cooling machine.

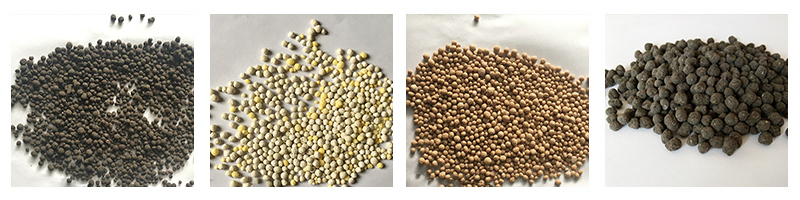

Sample particles