Fertilizer granulating by the organic fertilizer granulation machine, the material can be made of solid spherical particles when the moisture content between 20%~40%, which greatly saving energy and equipment, improve efficiency. In the drying process, its ad hoc polishing and mixing round function making the particles more smooth. The organic granulator can granulate pure organic fertilizer or mixed granulation of organic and inorganic fertilizer, without special requirement for granulation materials.

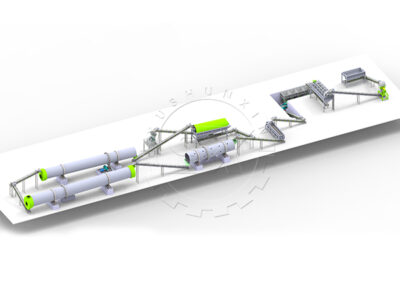

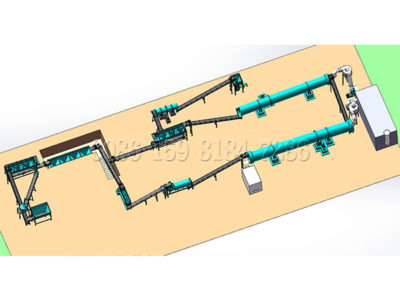

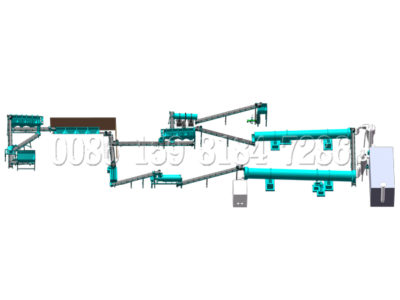

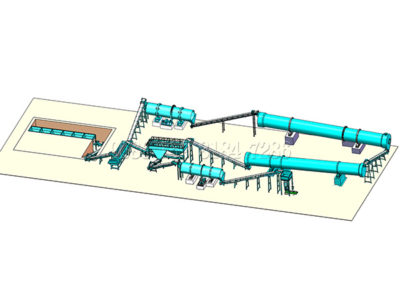

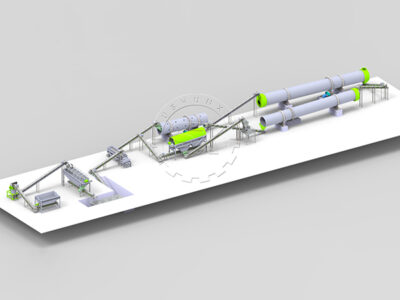

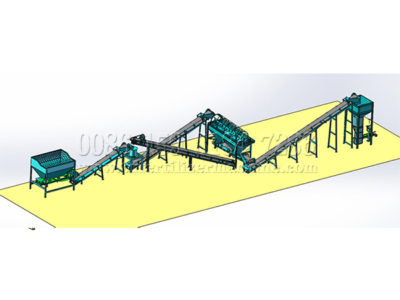

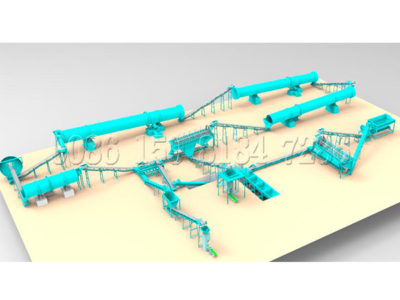

The basic process is outlined as follows:

- Fermentation process

After the completion of the fermentation, the material is dark brown, without fecal odor, but has a smell of compost. The methane is collected and enter into the methane boiler to burn through the water sealed tank and the flame arrester, which provide heat for the fermentation equipment, granulation, drying and the other units.

- Formulation process

(1)Crush

Crushing the organic ingredients (straw, soybean meal, bone meal, hoof powder, etc.) and inorganic fertilizer.

(2)Formulation and mixing of raw materials

The formula of organic and inorganic materials is mixed according to different products, and well mixed in the mixer.

(3)Water content control

Add organic matters such as straw powder or peat, which should be with high C/N ratio and low water content. The amount should be charcoal 6 tons / day, peat 6 tons / day, straw 18 tons / day. The water content of raw materials after the treatment should be 60%-65%, and the C/N ratio 20-30. The substance added must be broken sufficiently.

- Granulating process

(1)Crush

Crush the material after 1 days of fermentation. Drying, crushing and screening the fermented organic materials.

(2)Formulation and mixing

According to the formula, automatic formulating and mixing the nitrogen, phosphorus, potassium and fermented materials and transported to the new type organic fertilizer granulator for granulation. The formula of organic and inorganic materials is mixed according to different products, and well mixed in the mixer.

(3)Granulating

The production of biological fertilizer is mainly organic matter, the cellulose is much and the forming condition is poor. And because of adding live bacteria group with fertilizer making function, so the production process should not be exposed to high temperature. Therefore, for the production of organic biological fertilizer, it is better to adopting new type of organic fertilizer granulator and wet granulation process. After granulation, the materials are fed into the drying machine by belt conveyor for drying. The particle diameter is 3.0-4.0mm, and the granulation rate is more than 70%.

(4)Drying

In the bio-fertilizer production process, not only the water content of formed particles are generally exceed the index, so that need for low-temperature drying, but also the water content of the organic matter after fermentation is 30% ~ 40%, granulated particles generally in 15 % ~ 20%, while the quality index of fertilizer requires less than 14% moisture content, so the materials need for drying treatment. Therefore, the drying section is an indispensable process in the production process of biological fertilizers, which directly affects the yield, quality and energy consumption. It is very important to select the model specifications of the dryer and control the process conditions.

(5)Cooling

Finally, the dried material will be transferred into the cooling machine for cooling through the belt conveyor. The cooling process is mainly to use the blower to send the natural air through the pipeline into the cooling machine to cool the materials.

The cooling material will be transferred into the screening machine to screen: the large particles of material after crushing and the powder screened out will return to the granulator through returning conveyor to re-granulation; the qualified fertilizer particles will be delivered to the automatic packaging system for packaging.

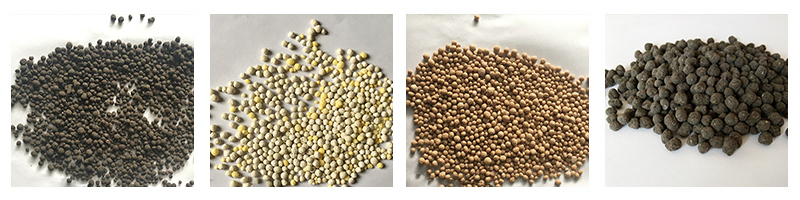

Sample particles