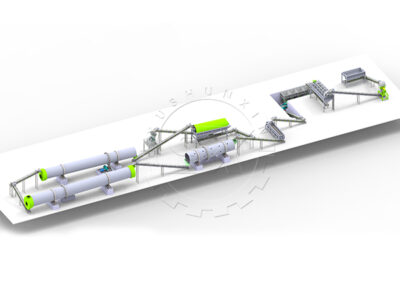

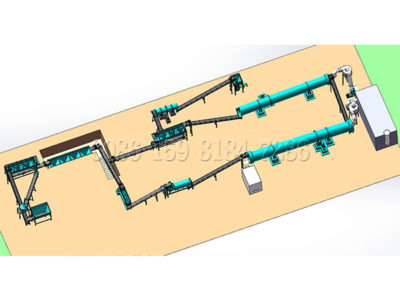

The production process of disc fertilizer granulator is short, simple structure, less investment and easy to operate. It is suitable for small and medium enterprises. The size of the organic fertilizer particles is determined by the inclination and the rotational speed of the disc, and the inclination and the rotational speed of the disc granulator disc can be adjusted. Therefore, the disk granulation process has a wide range of control of the particle size, and it has strong adaptability. The granulation rate is very high, reaching 70% to 90%. Direct viewing operation, users can master the operation situation of the equipment at any time. It can be timely adjusted if found any abnormal.

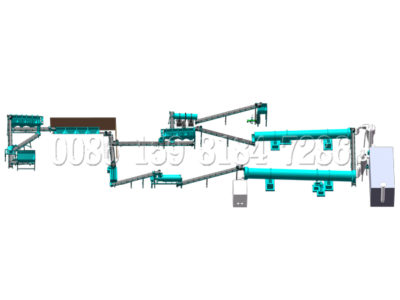

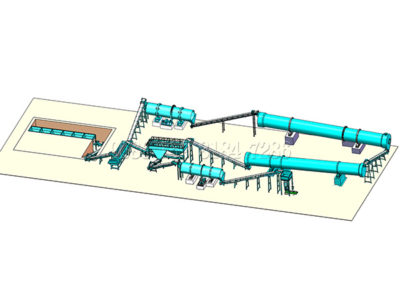

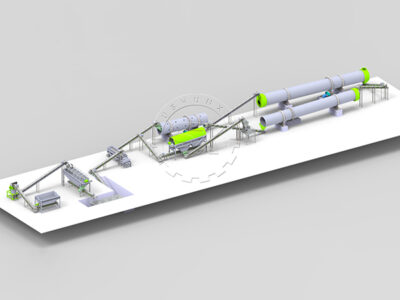

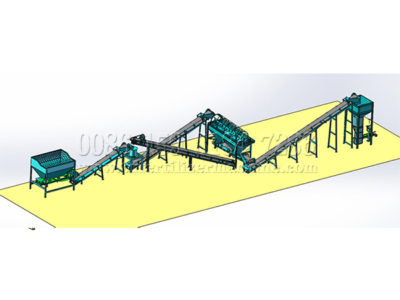

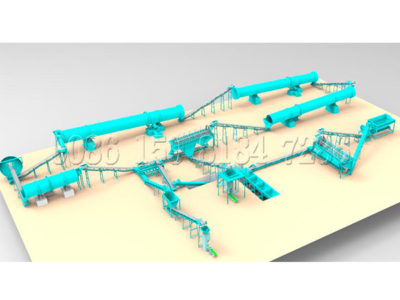

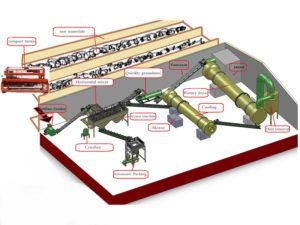

Brief introduction of livestock manure organic fertilizer disc granulation process:

- Directly transport the processed poultry manure to raw material silo (or raw material mixer).

- Transfer the poultry manure to the material distributor and evenly add the materials to the rotating disk of the disc granulator. A liquid component or a suitable amount of water is sprinkled on the material in the disk by a liquid distributor of disk granulator to satisfy the required amount of liquid content for pelletizing. The rotating disk and disk edge produce friction and centrifugal action on the material, cause the material to produce circumferential movement, so that the particles kneading and extruding between each other and gradually aggregated into balls. Due to the different weight of particles, the gravity and centrifugal effects are different. When the gravity and centrifugal effect are big enough to overcome the friction between the particles, then the particles will be thrown outside the disc, and smaller particles remain in the disc continue to aggregate fine particles.

- Transfer the particles to the organic fertilizer drying machine.

- Deliver the dry particles to the hot screening to sorting particles: small particles directly back to the disk material distributor, as the core continue to participate in the adhesion into balling particles.

- Deliver the qualified particles to organic fertilizer cooling machine, cooling fertilizer particles through natural air or forced air.

- Transport the cooling fertilizer granules to the screen machine. The large particles will be crushed by the crusher and then return to the disc material distributor.

- The qualified products will be sent to coating machine for coating.

- Deliver to the full automatic packing scale to weighing, packing and put in storage.

- Dust in drying, cooling and the workshop will discharge after three stages treatment: cyclone dust collector, labyrinth dust chamber and wet scrubbing.

Zhengzhou Shunxin Engineering Equipment Co., Ltd can help to design the 10 thousand -50 million tons per hour of organic fertilizer production line and the workshop according to customers’ requirements, as well as provide complete sets of organic fertilizer production equipment, complete sets of BB fertilizer production, organic and inorganic fertilizer production equipment, high, medium and low tower fertilizer equipment, rotary drum compound fertilizer production line, urea formaldehyde fertilizer equipment, ammonia acid fertilizer equipment, ammonia fertilizer equipment, roller extrusion granulator, drying and fermenting equipment for chicken manure and other high humidity materials and so on.

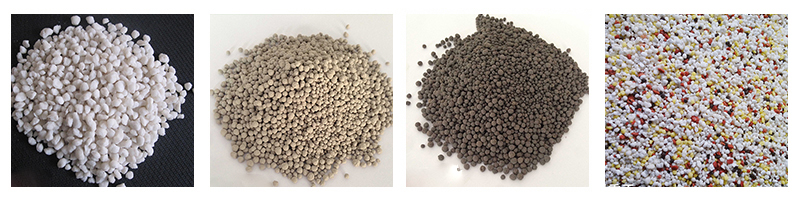

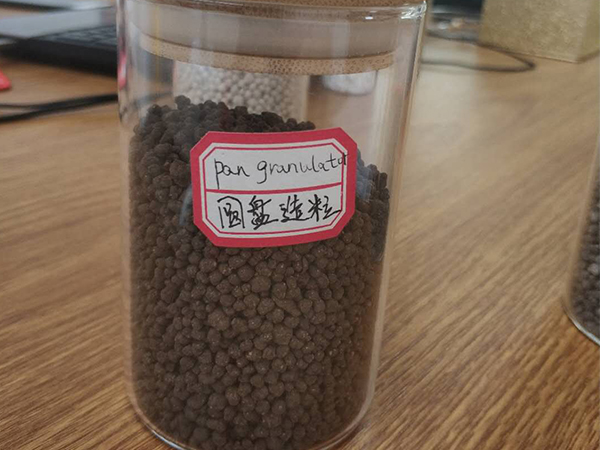

Sample particles: