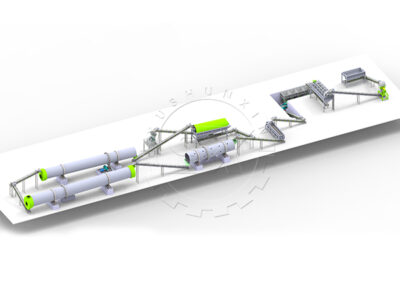

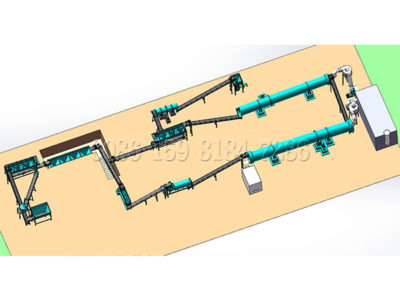

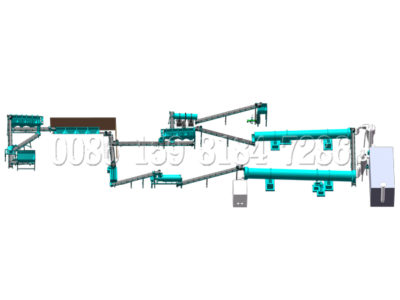

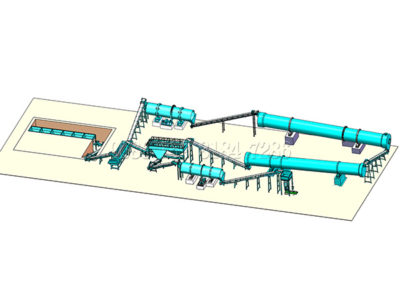

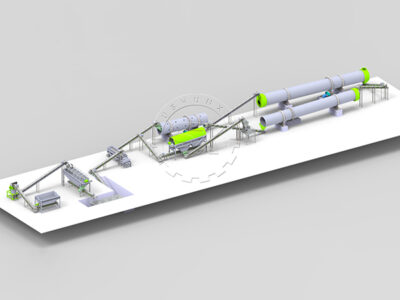

The fish protein water-soluble fertilizer production line utilizes enzymatic hydrolysis to break down proteins in fish waste into amino acids, creating fish protein water-soluble fertilizer. The equipment includes an industrial pure water machine, raw material pulper, high-temperature sterilization reactor, enzymatic hydrolysis reactor, solid-liquid separation equipment, buffer tank, solid metering equipment, liquid metering equipment, cooling finished product tank, and filling production line.

Production Process

1. Raw Material Preparation

Fish Raw Materials: Select protein-rich fish or fish by-products, such as fish bones, fish skin, fish entrails, etc.

Other Raw Materials: Including chelating agents, stabilizers, preservatives, etc.

2. Fish Raw Material Processing

Cleaning: Clean the fish raw materials to remove impurities.

Crushing: Crush the fish raw materials to increase surface area for subsequent hydrolysis treatment.

3. Protein Extraction and Hydrolysis

Enzymatic Hydrolysis: Use protease to hydrolyze the fish raw materials, breaking down proteins into amino acids and small peptides. The enzymatic hydrolysis process requires temperature and pH control to ensure optimal enzyme activity and hydrolysis efficiency.

4. Filtration and Concentration

Filtration: Filter the hydrolyzed mixture to remove undissolved solid impurities.

Concentration: Concentrate the filtered liquid, typically using vacuum concentration or membrane separation technology, to increase the concentration of effective ingredients in the product.

5. Additives

According to the product formula, add chelating agents, stabilizers, preservatives, and other additives, and mix uniformly. These additives help improve product stability and shelf life.

6. Blending and Homogenization

Blend the concentrated liquid with additives uniformly, and perform homogenization if necessary, to ensure product consistency and uniformity.

7. Quality Inspection

Conduct quality inspection on the blended product, including amino acid content, pH value, heavy metal content, microbial indicators, etc., to ensure the product meets relevant standards.

8. Packaging

Package the qualified fish protein water-soluble fertilizer, usually using moisture-proof and anti-oxidation packaging materials, seal and label the packages.

9. Storage

Store the packaged products in a cool, dry warehouse, avoiding direct sunlight and high temperatures.

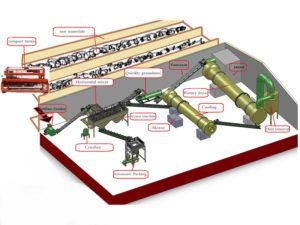

Features

1.Fish Meat Pulper: The fish meat pulper can fully grind fresh fish meat and fish waste (fish heads, entrails, fish skin, fish fins, fish scales, fish tails, fish bones, and residual fish meat) to improve enzymatic hydrolysis efficiency and reduce impurities.

2.Industrial Pure Water Machine: This machine includes dual-stage filtration with quartz sand and activated carbon, along with RO membrane filtration. The pre-filtration can remove particulate impurities, fibers, suspended solids, colloids, residual chlorine, detergents, organic substances, odors, colors, and carcinogens like trichloromethane. The reverse osmosis membrane intercepts organic salts, heavy metals, chemical pollutants, bacteria, viruses, and pyrogens, which are discharged with the concentrated water, while water molecules and oxygen molecules pass through the membrane to form soft water.

3.Enzymatic Hydrolysis Reactor: The reactor has a constant temperature function to ensure stable temperature during enzymatic hydrolysis. It features a combination stirring form with a built-in scraper cleaning device. Optional stirring speed adjustment function is available, suitable for various raw material concentrations.

4.Three-stage Series Sealed Filtration: This process uses three-stage series sealed filtration to reduce water-insoluble substances while also lowering equipment investment costs.

5.Closed Buffer Tank: The use of a closed buffer tank reduces the risk of semi-finished product deterioration.

6.Element Digester: The element digester in the fertilizer production stage has chelation and complexation functions and is equipped with a constant temperature function.

7.Addition of Amino Acid Powder: Amino acid powder raw materials can be added during the fertilizer production stage to increase the amino acid content of the final product.

8.Cooling Coil in Finished Product Tank: The finished product tank is equipped with a cooling coil, which circulates water connected to a cooling tower, to cool the fertilizer product inside the tank.