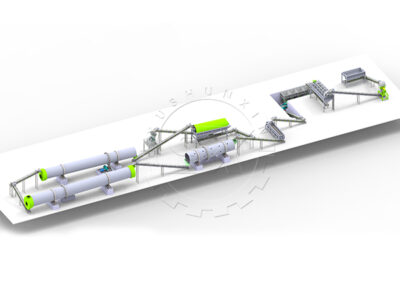

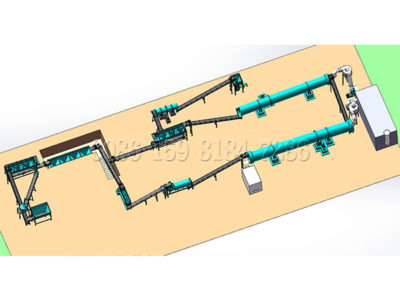

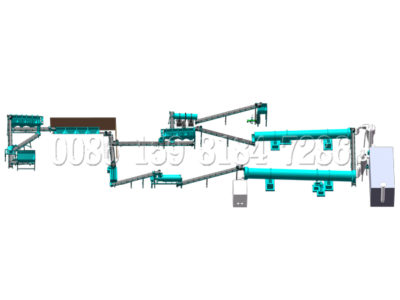

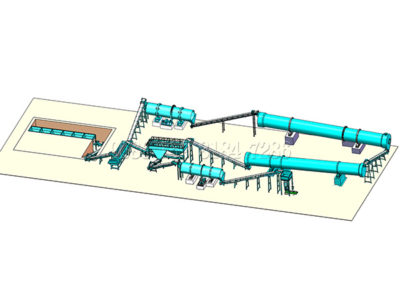

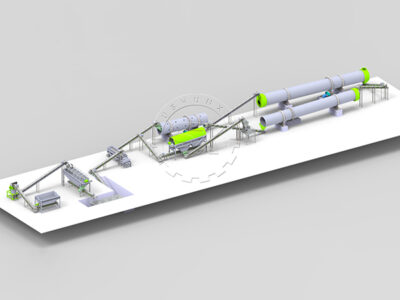

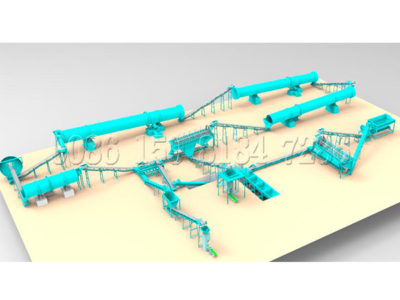

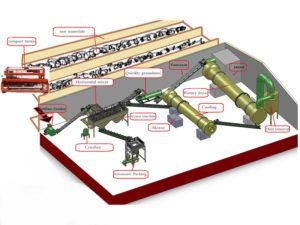

The organic fertilizer production process generally includes: raw materials matching (chicken manure, etc.) → dry sterilization → ingredients mixing → granulation → cooling and screening → metering sealing → finished storage. A complete set of organic fertilizer production line mainly includes fermentation system, drying system, deodorant and dust removal system, crushing system, batching system, mixing system, granulation system, screening system and finished product packaging system.

Equipment needs of all links of organic fertilizer production process:

1. The fermentation system is made up of feed conveyor machine, biological deodorization machine, mixing mixer, special lifting compost turner machine and automatic electric control system;

2. The main equipments of drying system are belt conveyer, rotary drum drier, cooling machine, draught fan, hot blast stove, etc.;

3. Deodorant and dust removal system consists of settling chamber, dust removal room and so on. Zhengzhou Shunxin Engineering Equipment Co., Ltd provides drawings free of charge and guide users to assembly for free.

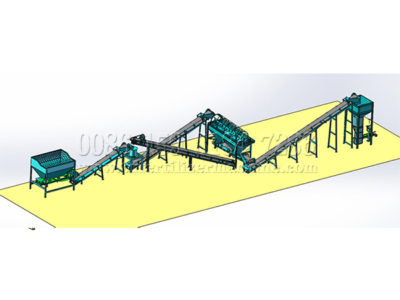

4. The crushing system includes the new semi wet material crusher, LP chain crusher or cage crusher, belt conveyor and so on.

5. The batching system consists of electronic batching system, disc fertilizer feeder and vibrating screen, which can be configured with 6-8 kinds of raw materials at one time;

6. The mixing system has an optional horizontal mixer or a disc mixer, a vibrating screen, a mobile belt conveyor and so on;

7. The granulation system needs to use the granulator equipment, optional granulation equipment including compound fertilizer roller extrusion granulating machine, disc fertilizer granulator, flat-die fertilizer granulator, bio organic fertilizer granulator, organic fertilizer granulator, drum granulator, round polishing machine, compound fertilizer granulating machine etc.;

8. The screening system is mainly completed by the roller screening machine, and you can set up one level screening machine or two level screening machine, so that the finished product rate is higher, and the particles are better;

9. The finished products packing system usually includes electronic ration packing scale, storage bin, automatic sewing machine and so on. Therefore, the automatic uninterrupted production of the organic fertilizer production line can be realized.

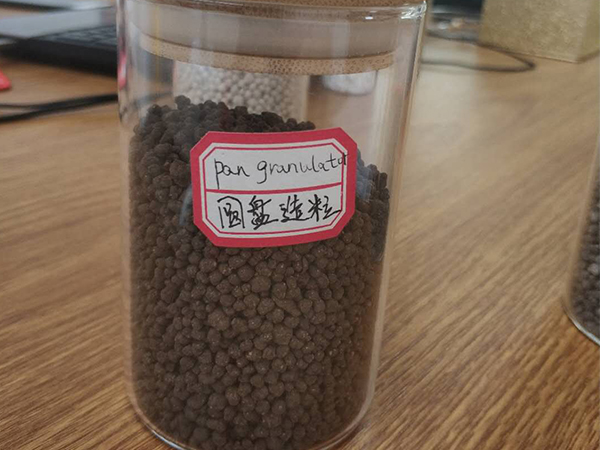

Example Pellets