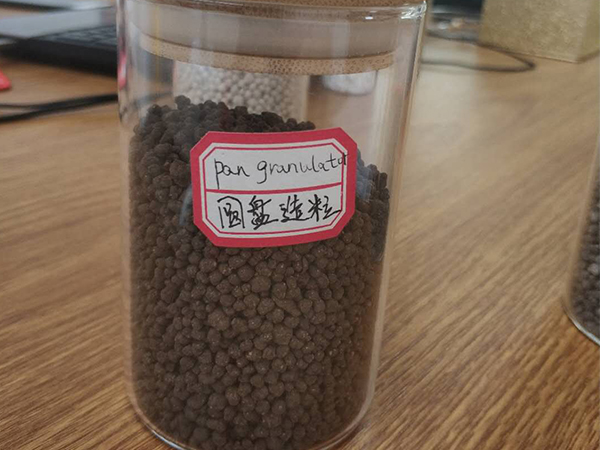

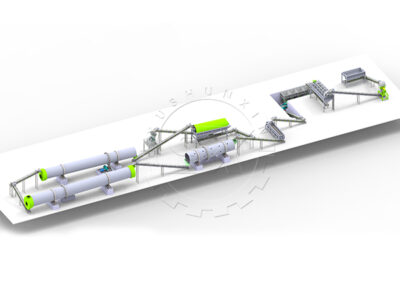

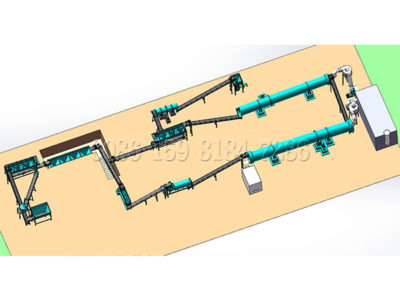

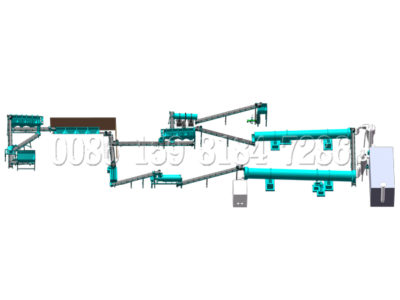

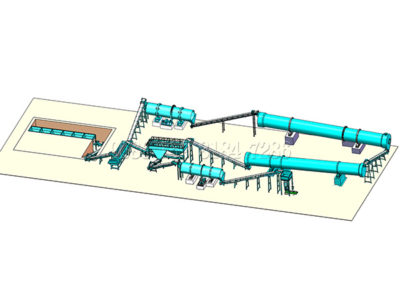

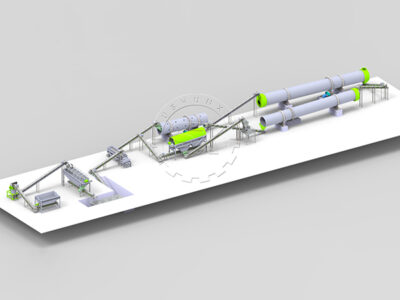

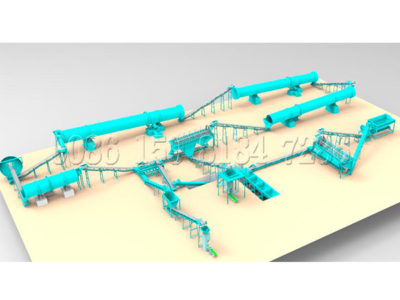

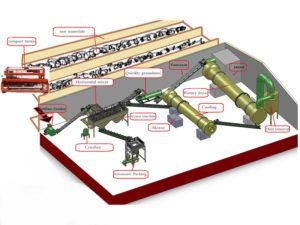

All the organic fertilizer materials can be granulated by pan granulation process. After drying and fine grinding, and mixing with proper amount of chemical fertilizer, transport the raw materials into the disc. The mixture is sprayed by humidifier and adhered to each other, wrapped into granules along with the rotation of the disk. Drying again, and then screening and packing into bags.

The disc granulator adopts a circular arc structure, whose rate of granulation can reach more than 93%. The reducer and motor are drove by flexible belt, which can start smoothly, slow down impact force and improve service life of equipment. The plate bottom is strengthened by multiple steel plate, so it’s durable and never deformation. Thickened, weighted and firm base design, without anchor bolts and stable operation.

The main gear of the granulator adopts high frequency fire, and the service life is doubled. The granulating pan I lined with high strength glass steel, which is anti-corrosion and durable.

The disc fertilizer granulation machine has the advantages of uniform granulation, high balling rate, stable operation, strong and durable, long service life, etc. Well received by most of users, it’s an ideal product chosen by the vast number of users.

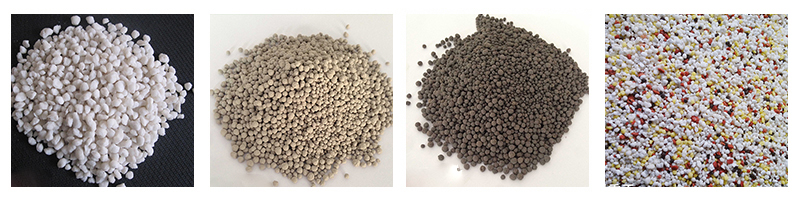

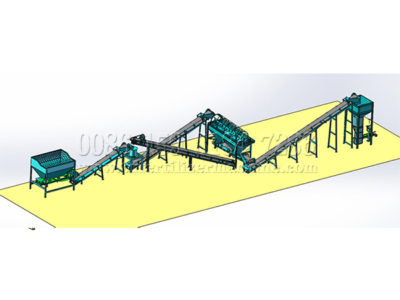

Sample particles: