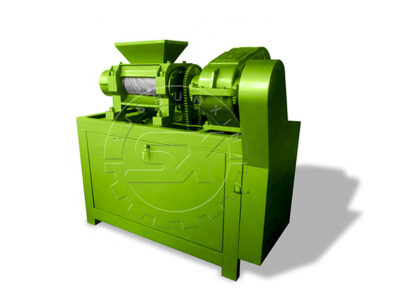

Rotary drum granulator is a molding machine that can make material into a particular shape. It is one of the key equipment of the compound fertilizer industry, which suitable for cold or hot granulation and mass production for high and low concentration compound fertilizer. The main work method of the rotary drum granulator: aggregation wet granulation technology. With a certain amount of water or steam, the basic fertilizer humidifying in the tank and occurring sufficient chemical reaction. Under a certain liquid conditions, with the rotation of the rotary drum movement, so that produce a squeeze force between the material particles and agglomerate into balls.

We adopts special rubber liner or acid-resistant stainless steel liner into the rotary drum, and achieve the functions of automatic scars and tumor removal, so that you can cancel the traditional scraper device. This machine has so many characteristics such as high balling strength, good appearance, corrosion resistance, wear resistance, low energy consumption, long service life, convenient operation and maintenance and so on.

Rotary drum granulator features:

1, The balling rate is more than 90%, with small amount of return material, small size of feed back and can be re-granulation;

2, By steam heating, it can improve the temperature of material, so that the water is low after ball forming, thus improve the drying efficiency;

3, With rubber engineering plastics for lining, raw materials is not easy to stick, and play a role in anti-corrosion and insulation;

4,Large capacity, low power consumption and maintenance costs.

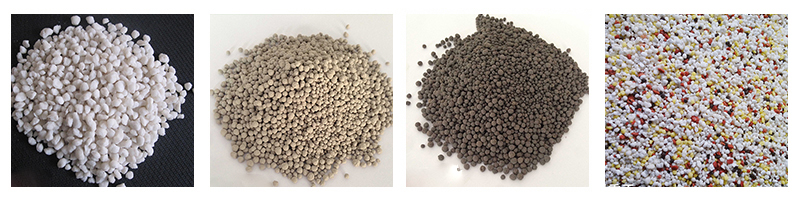

Pellets made by rotary drum granulator:

The main motor drive the belt and pulley, and transmits to the driving shaft through the reducer. The counter open gears that installed on the driving shaft engaged with the large gears that fixed on the machine body and work in opposite directions. The material enters into the cylinder through the feed end. Through the processing of the special internal structure, make the materials into particles and finally flow out of the outlet. As the material continues to enter and continuous rotation of the granulator, it will be able to achieve mass production.