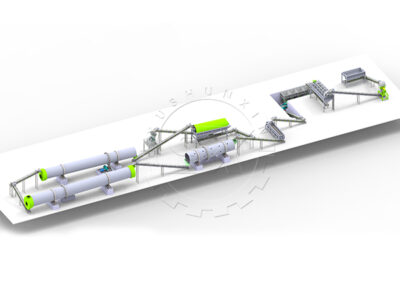

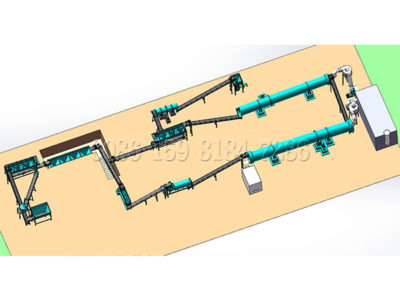

Shunxin series of disc fertilizer granulator, is a new type of inclined disc granulation equipment: the granulation rate is up to 95% or more. The main gear of the granulator adopts high frequency quenching and doubles the service life. The disc fertilizer granulator made by Shunxin adopts arc structure as a whole, the disk lined with high-strength glass fiber reinforced plastic, the bottom of the plate with a number of radiation plate to strengthen, so the disc will be durable and never deformation. Thicker, heavier, rugged base design, no anchor bolts fixed, smooth operation. The pelletizer of the disc fertilizer granulator has three discharge ports, which can facilitate the intermittent production operation and greatly reduce the labor intensity and improve the labor efficiency. Reducer and motor with flexible belt drive, so the machine starting smooth, slow down the impact and improve equipment service life.

Working Principles

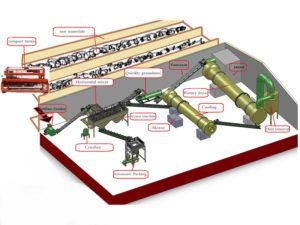

The main motor drives the pulley and belt, the drive the pinion through reducer. The pinion is engaged with the big gear that fixed at the bottom of the disk and work opposite to each other. The big gear are specially designed to fit on the spindle mounted on the rack adjustment disc to support the work of the entire granulator (used in conjunction with the sprayer). After entering the granulation plate, the raw materials are uniformly bonded and formed into spherical particles by the continuous rotation and spraying of the granulator. We have designed an automatic cleaning device in the upper part of the disc granulator to prevent the material sticky on the granulation plate, thus greatly improving the service life of the disc granulator. With the continuous rotation of the motor and the material continues to enter, finally it’s able to achieve the goal of mass production.

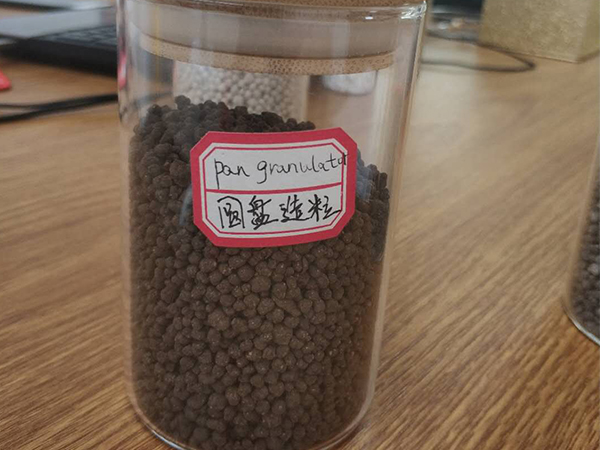

Pellets made by Disc Fertilizer Granulator:

Structural features

The disc fertilizer granulator machine can be divided into five parts:

First, the rack part: As the work of the whole body of the transmission part and the rotating part are supported by the rack, so the force is relatively large. Therefore our the frame parts of our machine are welded by excellent carbon steel plate and channel steel, also our machine have through strict quality certification and specific technical requirements, all have reached the requirements of the application of the machine.

Second, the adjustment part: the most important part of the disc granulation is the granulation plate, and the enter center of gravity of the granulation plate is installed in the adjustment part. Our company specializes in the use of excellent carbon steel plate and channel steel to welded, and through a rigorous quality certification, all have reached the requirements of the application of the machine.

Third, the transmission part: the transmission part of the whole machine is particularly important, the overall work is done in this line. The motor and reducer on the transmission adjusting rack are all choose ISO/9001 quality system certification of exemption products, reliable quality. The motor drives the pulley, the V-belt, the reducer and the pinion, the pinion drives the large gear of the granulation disk and then the granulation disc start to work. In addition, both the pinion and large gear are applied high-frequency quenching process, so the service life is twice the original. The entire granulation disk is fixed on the active shaft of the adjustment plate, the connection part of the stigma adopts taper fit, so the design is more reasonable.

Forth, the granulation plate part: The disc fertilizer granulator made by Shunxin adopts circular structure as a whole, the granulation rate can reach more than 92%. At the bottom of the granulation disk, we use a number of radiation steel plate to strengthen, so our machine will be durable and never deformation.

Fifth, the automatic cleaning part: this part installed above the granulation disc, into the box type, equipped with automatic cleaning board in the upper part to remove the material that sticks to the wall of the disk in the production process, greatly improving the service life of the machine, also saving labor.