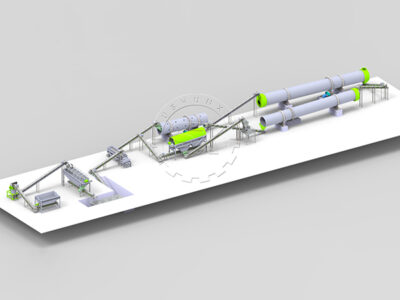

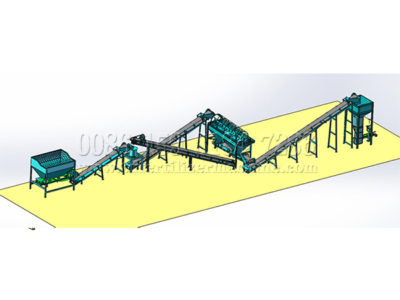

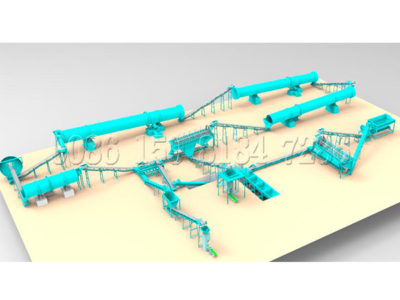

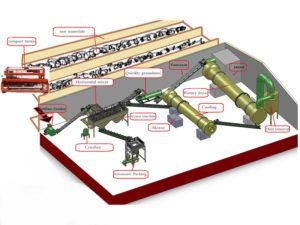

Full underground design, so that have no requirements on the plant height(this system can also be installed above the ground, but if installed on the ground, there will need to add bucket elevator or other raw materials lifting equipment). In essence, the production process of compound fertilizer is to separate or melting each raw material, then formulate the raw material proportioning scheme according to the requirements(including selecting a certain proportion of additives, etc. ), and mixing, granulating, drying, cooling, packing and so on.

Technological process:

Microcomputer control → belt scale continuous ingredients at the same time → large quantities of continuous mixing, continuous discharge → automatic packaging → finished products.

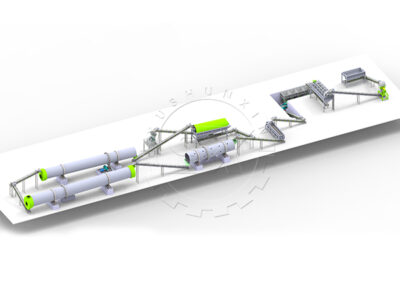

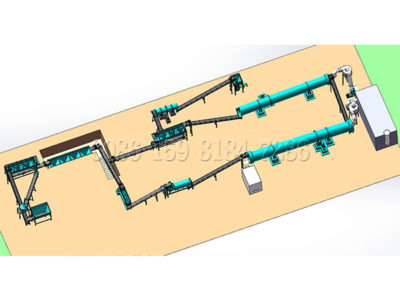

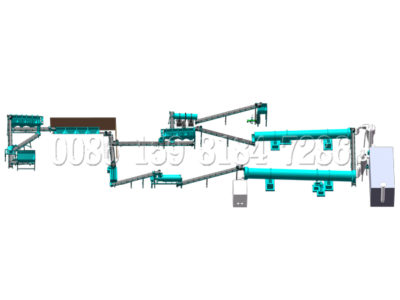

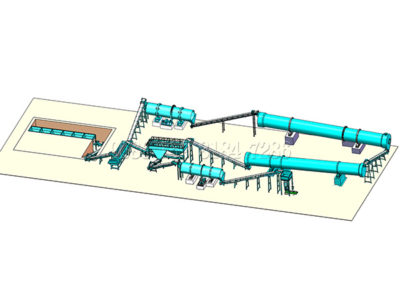

Equipment composition:

Microcomputer control system → Batch conveyor belt scale → Belt conveyor → Screw conveyor Mixer → Bucket Elevator → Automatic quantitative packing scale → Belt conveyor and Sewing Machine;

Production line structure and features:

- There are many kinds of ingredients. Batching with Microcomputer, which is high precision and fast batching. It is applicable to 3~12 kinds of materials and can be allocated 8~40 tons per hour;

- Economical and practical. Microcomputer control tends to be intelligent, automatic, low equipment investment and low operation cost.

- Batching system automation. Microcomputer batching system automation, automatic drop compensation, power-on self test , sound and light alarm. The utility model has the advantages of quantitative measurement, high measuring accuracy, simple operation and reliable operation.

- Intelligent mixing system. The lifting, mixing of raw material and discharging time can be set automatically, system automatically controls the running time according to the set parameters. Quick operation, high production efficiency.

- Computerized quantitative packaging system. Imported sensor and instrument with high measurement precision, batching accuracy less than 0.5%, packing precision less than 0.2%, reliable operation.

- Separate design of equipment structure. Individually designed the production line on the ground or under the ground according to user site.

- Convenient monitoring and inquiry. The equipment is able to print reports and inquire the accurate situation of instantaneous batching at any time. Equipped with field or remote monitoring system, connect with the large screen to display current formula.

- Long service life. All parts of the equipment are made of stainless steel plate with multi thickness and corrosion resistance to ensure long service life.

- Cost reduction. Microcomputer control, simple operation, the entire production line only need 3-5 people, which can save personnel and also greatly reduced electricity consumption.

Sample particles: